Science Behind Molded Cup Bras

Mausmi, is an established expert in the garment industry with over 13 years of experience. She is a entrepreneur and prolific blogger and a Professor also. Her brain child ThreadSol is a practical reflection of her ideology-“Buy what you need, use what you have!”

Mausmi, holds a Masters degree in Fashion Technology from NIFT, Delhi and is also B.Tech in Computer Science. She has been a part of the Nasscom Product Conclave, Bangalore and GTE Garment Industry Seminar, Delhi with the idea of addressing existing industry gaps and bridging the same.

She has been featured in over 20 trade Magazines and Journals. Mausmi also writes her own apparel blog called Stitch Diary- www.stitchdiary.com.

Prior to ThreadSol, Mausmi did apparel consultancy and training with Methods Apparel in South-east Asia. She has also worked as a faculty at NIFT and loves to teach whenever she gets an opportunity.

Traditionally bras were made with cut pieces sewn together to form a 3D cup to fit the breast profile. However, the sewing skill set requirement and high manufacturing costs dominated this technology. To address this issue, fabric of foams sheets molded to a 3D shape were started being used.

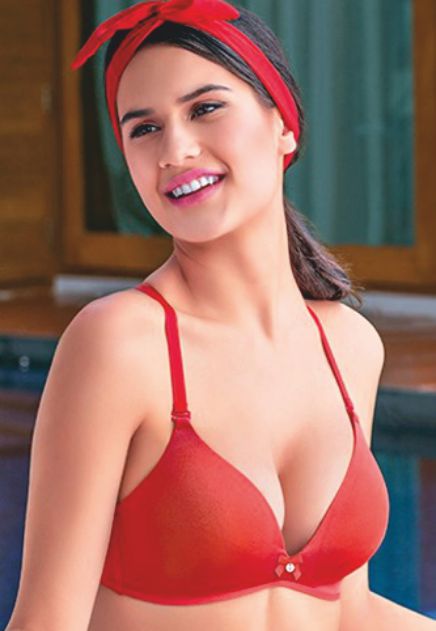

MOLDED OR SEAM FREE CUPS – LINGERIE

Molded cup bras have seamless cups with possibly thicker linings than the traditional one. It retains its shape due to the molding technology. The term ‘molded’ actually refers to the technology that is used to make the cups. The material is heated over a mold to provide the distinct shape to the cups. They are thus heat-molded round forms of synthetic fibers or foam. These cups are used in padded bras, t-shirt bras, contour bras, etc.

The Origin of Molded Cup Technology

The driving force for intimate apparel sector since the 1960s has been conformingsupport, light weight, and invisibility under outerwear. Wonderbra in 1974, developed and applied the thermal molding technology to create the first seamless cups bra ‘Dici’. However, lack of essential seam-bonding and welding technologies delayed this technology to reach a mass market.

Victoria’s Secret developed first seam free bra in 2002, where the underwire was sandwich bonded between the fabrics before molding into a one-piece bra. Other companies like Bogart opted for an alternative route. They bonded material over the face of molded cups using traditional sewing. Bogart’s range facilitated the used of decorative material and the Victoria’s Secret encapsulation of wire gave their product more underwire comfort and one-piece bra juristic appearance. Both these kinds offered a reduction in visible seam lines and improved comfort resulting from the elimination of the bulky seams.

The Reason behind Success of Molded Bras

Molded cups offer three basic advantages. Firstly, seamless finish gives a smooth appearance to the silhouette. Secondly, they provide sufficient coverage even without the hefty seams hence work best with fitted garments like t-shirts. Lastly, and most importantly, it offers a comfort level along with providing the proper shape.

Compared to the traditional cut-and-sewn bras, molded cup surface allows a natural configuration with unlimited design, comfort, hand feels and support possibilities.

The countries that mastered this technology

Asia, mainly China is the global hub of molded bra manufacturing technology. The Chinese town of Gurao is known for its lingerie industry and offers molding technology to global buyers. Apart from that Egypt, Turkey, Tunisia, France, South America and Italy have also mastered molding technology.

Technological developments in China

China exports lingerie to over 200 countries globally. It caters to US, Japan, Europe, Hong Kong and Romania lingerie markets. Being on the most lucrative product groups for China, universities in the country also offer Degrees in Bra Studies and have atown (Gurao, Guangdong) specifically known as the “Town of Underwear” due to the presence of most of the lingerie producing factories of the country here.

Saturation of domestic and global markets and fierce competition is forcing Chinese lingerie industry to consolidate. This consolidation is not just eradicating smaller players, but also changing the technology Chinese manufacturers used to prefer traditionally. Hence, Chinese manufacturers catering to high and low-end markets both are shifting towards the trends of molded and spacer bra technologies. Chinese manufacturers catering to the low-end market also are shifting their focus to molded bras from cut-and-sew pieces due to the manufacturing costs savings, form precision, quality, and higher global demands.

Bra Molding Technology

In the molding process, a pliable material is given a specific shape by forcing it into a mold and holding it within a rigid cavity at high temperature. After reaching the softening temperature, the morphological hard segments and the soft segments within the material are rearranged to enable its conformity to the desired shape.

There are two major molding machines used, namely, bullet head molding machine used on fabrics and a contour molding machine used on foam.

Fabric Molding: Bullet head molding is generally used on fabrics. The fabric is placed on an open plate and a heated bullet head is driven downwards pushing the fabric down in the cavity. Heat and pressure are maintained for 30 to 60 seconds to develop permanent 3D shape.

All knit fabrics made from synthetic fibers are suitable for molding. Non-woven and spacer fabrics are fit for this purpose, as per the need of the design.

Foam Molding: Contour molding machine has apair of metal molds with desired profile shape. Here the heated molds stretch and compress the flat foam sheets between them at apreset temperature. The high temperature in this method is maintained for a minute to allow it to transmit through the foam sheets.

A lot of the issues with molded cup bras and certain body types can be resolved through proper fit and the right design.

Our molded bras vary in design and cut, so try a few different styles to see if there’s one that works best with your breast size and the distribution of your breast tissue. A properly fitted molded bra can be a glorious thing!

Who should wear a molded bra cup?

Molded bras are favorites with:

- Women who want a smooth, rounded shape

- Women whose breasts are slightly different sizes or shapes

- Women who have sensitive nipples and want a bra without seams to avoid irritating the nipples When is a molded cup bra not ideal for a certain body type?

- If your breasts vary significantly in size; one bra cup may not be filled completely and could ‘flatten’ or appear squashed or deformed under your clothes (unless you use an insert)

- Women with very large breasts may find they prefer a multi part cup for added shaping and support, a molded bra may not provide the shaping and support you want

- Women with loose breast tissue on top; if you do go with a molded cup bra, make sure you get the appropriate cup size – if the breast tissue doesn’t fully fill the cup, the top of the cups may ‘cave in’ and not look right under clothes

TYPES OF MOLDED BRAS

There are many different kinds of molded bras. Whether it’s a contour, push up, padded, or 3D spacer molded bra.

When worn, the cup formed by the molding process molds breast tissue to the shape of the bra. Typically, a good way to tell if a bra is molded is by setting the bra down, cups facing up. If the bra cups stay up, with space for breast tissue, it’s a molded bra. If the cups fall down and lay flat with the ground below it, it is not a molded bra.

In the history of bra manufacturing, molded cups have expanded in variety and size. In the past, molded cups were typically very firm, thick, or only padded. In recent bra history, less structured, flexible, and breathable materials have become very popular. There are so many options and styles to choose from!

T-ShirtMolded cup bra.

A molded t-shirt bra is generally one that is smooth or seamless. That seamless look is easily achieved in the molding process during manufacturing. This kind of bra is often called a t-shirt bra because the smooth material will provide a clean, seam free look under the thin or stretchy material of a t-shirt. This kind of sleek molded bra is often a basic in women’s bra wardrobes because it can be worn under many different tops or dresses, and are available in many different styles like plunge, full coverage, push up, padded, convertible, or strapless.

A molded bra can hide nipples? Depending on the thickness of the bra, and the shape of your nipple, wearing a molded bra is an easy way to create modesty

Padded, Push Up, Contour

Some molded bras have padding or push up, but not all. It’s a common mistake that women make when they think a molded bra will add volume to her cup size. In fact, a molded bra will just form her bust to its shape. A molded bra with padding or push up, however will add volume and size.

A padded bra, or sometimes called a contour bra, is not exactly the same as a push up. Padding refers to the thickness of the cup. Some padded bras are thicker than others. The entire molded cup will be thicker, creating a fuller looking cup when worn. Padding is a great option for women who want a bigger looking bust, want to create a sleek bust appearance, or want to even out their breasts. Breasts are commonly slightly uneven, and a padded bra that fits to the fuller bust, will create an even shape underneath clothing.

A push up bra adds volume to your bust by using a foam bump in the bra. Depending on where the bump is placed, this material will “push up” your breast tissue to create more fullness on top, or bigger volume. The push up portion of this kind of bra is typically built right in to the inside of the bra cup.

Some styles, however, offer a removable push up inserts called cookies. They are made of fabric, foam, or air or water filled plastic. Typically, they will sit in a mesh or fabric pocket inside the bra cup and can be taken out or put in with ease.

The molded cup, which is usually thicker, will hide any insert from showing through the bra and looking awkward under clothing. This is a great option for a woman with uneven breasts as well. While a padded bra can cover over uneven busts to give the illusion of symmetry, a bra with removable push up pads can create even cleavage. Simply by removing the pads from one side and leaving them in the other, you can adjust the necessary amount of push up and even out your silhouette.

Underwire and Non Underwire

Molded bras are available in both underwire and non underwire styles. Unlike a typical triangle or soft cup bra, the molded bra without underwires can still form breasts to its shape.

Underwires are common in molded bras because they offer the kind of shape that is most popular today: lifted, round, smooth, and separated. Though it’s not necessary for a woman to wear an underwire in her bra, it’s a popular choice for today’s fashions and the look most women desire. If you are having trouble with underwires in your bra, make sure you are wearing the right size, and style for your body. Often, a good fit will solve any problems with comfort.

Spacer Molding

Newer to the lingerie world, spacer moldingis a quite different option than those offered by molded bras of the past. Spacer molding is actually a kind of breathable knitmaterial. It has the same shape as other molded bras – when you lay it down, the cups stay up – but is much more flexible and breathable. Think of spacer molding as a mini knit sandwhich – a thin layer of material on the top and bottom sandwiches a very fine knit. This creates space in between the layers, and also a “springy” feeling when you press down on the material. It’s soft, malleable material is usually referred to as a more natural looking option than stiff, very firm contour or molded bras.

Spacer molding is great for women who prefer or need a more breathable material than thick molded cups. The weave of the knit allows more airflow. If you are going through menopause, live in a hot climate, or suffer from heat sensitivity, this is a great option for you.

In addition to the breathability, spacer molding is also more flexible than other molded bras. This is especially helpful for women whose bust may not match up perfectly with a molded bra. The flexible bra will still for your bust to its shape, but can also give a little and form to your shape. This happy medium makes a lot of women very happy. If you’ve ever struggled to fill up the top of a firm molded bra, or spilled out the top, this kind of bra material can help. Of course, you should also make sure that the spillage or gapping isn’t caused by wearing the wrong size first, then move on to style.

Other kinds of molded bras

Strapless: Molded cups are popular for strapless bras because the cups maintain their shape without the help of a strap. While it’s not necessary to have a molded cup strapless bra, they have been the most popular fashion choice among bra wearers in recent history.

Nursing: Molded cups are a recent development for nursing bras. Nursing moms crave the shape provided by molding, and need the functionality of the nursing clips and sling. If a nursing bra is too thick or molded, folding it down over and over again to allow the baby to get to the breast can invert and ruin the cup. A molding with a bit more flexibility is more desirable.

Sports: Molded sports bras provide the same shapely function as everyday molded bras. In addition, they can often eliminate the “uniboob” look that often comes from a stretchy cup, non molded sports bra.

Lace: Can a lace bra be a molded bra? You bet! While a true lace bra, which is made of just lace and other bra components, will not be molded, there is another option: a molded bra with a lace overlay. This popular option combines the beautiful aesthetic of a lace bra with the shape and contour of a molded bra.

(With additional inputs from LnL

Editorial Team)