Manufacturing units play a very important role in production. Setting up at the right place and the right time is a very important factor and then there arises the question of being aware of the future and thereby taking the first mover advantage and set up galloping through the hurdles without looking back. As a tribute to the fast advancing manufacturing units for the lingerie industry, we have thought of taking a plunge to un ravel the depths of manufacturing at important hub towns of India. And Bhiwandi marks the first in the series.

Advantage Bhiwandi

- Lower property price

- 2nd largest power loom centre in India

- The textile industry manufacturers get TUFS advantage

- Connectivity with Mumbai, Ahmedabad, Nashik and Ratnagiri

- Octroi benefits are noteworthy

- Duty prices are lower for water and electricity

- Easy labour availability

Bhiwandi is a city, in the district of Thane, in the western state of Maharashtra, in India, located 20 km to the north-east of Mumbai and 15 km to the north-east of Thane city.

The economy of Bhiwandi is mostly dependent on the power loom industry. The decline of Mumbai’s textile mills spurred the growth of the power loom sector. In order to meet the demand for grey fabric, power loom centres sprang up in various parts of the State. Textile and migrant workers especially from Uttar Pradesh (mainly from Azamgarh, Wasadargah (Siddarthnagar) and Varanasi) and Bihari migrant labours came in droves to find work at these centres.

Bhiwandi eventually became the 2nd largest power loom centre in the country after Surat. The bloom of cloth oil and looms still attract worker from different states to come and find a suitable jobs. The State government estimates that over 40 lakh people are dependent directly or indirectly on the looms of Bhiwandi. The Power loom industry is the main reason for huge number of floating population. Bhiwandi is the ‘richest city in Thane District’. Bhiwandi also has become the ‘highest paid octroi’ with the largest godown present in Asia owned by local politicians in and around Bhiwandi. Bhiwandi is the `mother godown’ for several industries and the nodal up-country booking and transit point for several goods transporters owing to the octroi benefits that can be availed of here.

The city of Bhiwandi is known for its textile industry has the largest number of power looms in the country and is dubbed as ‘Power loom centre of India’. The growing importance of government policies and subsidies and the marked growth of the textile industry over the last few years made way for a positive business podium at Bhiwandi. Through the last couple of years Bhiwandi has mapped several success stories so far. A shift from shuttle to shuttleless looms, an opening for the processing industry etc. Bhiwandi today weaves nearly a third of the cloth that the country wears.

” I think our industry is slowly moving beyond the traditional concept of small manufacturing units/ galas in different pockets of the city. A lot of international brands are entering India & in order to compete, we need to beef up our manufacturing facilities in terms of systems, procedures for them to be on par with international standards. And to do that is only feasible in dedicated manufacturing hubs which provide all the synergies for manufacturing, explained Monal Vora, Head- Online Marketing, Red Rose Textiles Industries Pvt. Ltd

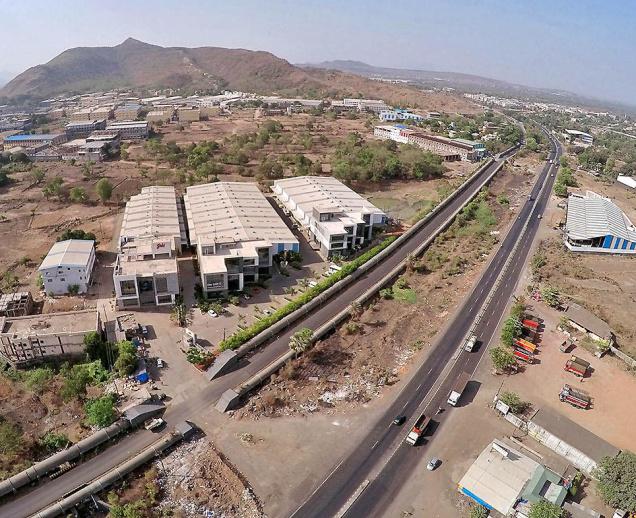

Back in 2006, Bhiwandi’s fortunes may have been waning & waxing with its power looms losing steam, but new hopes were poured in into this little energetic town to turn it into a hub of industrial and textile activities. Thanks to a textile-cum-industrial park on a sprawling 227 acres of land on the Nashik Highway, just a stone’s throw from the heart of this famed power loom town, which is less than an hour’s journey from Mumbai.

The dream project is the brainchild of Yogi Realty Pvt Ltd, promoter of Textile-cum-Industrial Park. The textile park named Pratik Textile Park, came up 10 years back in 76 acres of land with the rest of 151 acres earmarked for the industrial units. The textile park falls under the Scheme of Integrated Textile Parks (SITP), which attracts a host of incentives that includes a subsidy of Rs 40 crore. This park is an eco park with state-of-the-art facilities. Common effluent plant, gas & solar power for streetlights, Power and Water self sufficiency are a few of the long list of incentives offered at the park.

Well equipped with additional facilities like design centre, testing laboratories, library, weaving support centres, export marketing centres and textile technology centre the park stands strong as a much coveted manufacturing zone in Bhiwandi. The textile park offers space on lease basis while the industrial park works on ownership basis. Since TUFS benefits is available for the textile units, the entrepreneurs take advantage of all the incentives and tax benefits offered.

“The first obvious advantage is the cost benefit of real estate. You can get a manufacturing space at almost 1/3rd the cost that you have to pay in the suburbs. Secondly, since it’s been developed as a manufacturing hub, there are large factories & galas available to set up manufacturing which is now difficult to find in cities. Also, there is a lot of encouragement from the government in terms of power/ water tariffs, duties etc. I can sense an increasing optimism in the industry about setting up facilities in this sector which are positive signs for the industry as more & more businesses are coming to Bhiwandi. Also, simultaneously, the Government understanding the importance of efficient logistics is working fast towards improving the roads & other infrastructure,” Monal Vora further articulated.

Red Rose has 8 thousand plus sq area dedicated to their manufacturing in Bhiwandi and the brand is optimistic that The next 2 years are critical & there will be a big increase in the number of businesses setting up units here, which in turn will result in an improvement of allied activities & infrastructure. Believing in a forward growth Red Rose is planning to expand aggressively and expand over 20 thousand sq ft area soon, with a projection and planning to accumulate another 10 thousand Sq ft area over the next 5 years.

Apart from Pratik Textile Park, Asmeeta TEXPA by Asmeeta Infratech Pvt Ltd (SPV) is the first approved Integrated Textile Park in MMR under Scheme for Integrated Textile Park (SIPT) by Ministry of Textile, Government of India. Spread across 60 acres, the park is providing world class, need-based infrastructure and state-of-the-art technology to the unit holders in the park. Ackruti City Ltd, which has a rich & varied experience in the development of various commercial & residential spaces, malls and infrastructure like IT parks & biotechnology Parks is promoting the park.

Years of International exposure and visiting lingerie manufacturing units abroad, planted a dream in Sonari Director Dipesh Kubadia’s mind. He wanted to set up a manufacturing unit in India, that complies to every International standard and is in no way lesser than an International set up. He has finally successfully set up his dream project, with 220 running machines specially imported from Europe and Singapore. With 7 lines of production running simultaneously, the Sonari factory set up sometime in March last year has been completely worked along the lines of transparent quality production. Finishing, that too a neat and uniform one over a minimum lead time, makes the production capacities smart and highly innovative. Also a first one in its league.

Sonari truly paved the way and moved to Bhiwandi to take it forward in manufacturing and redefine lingerie manufacturing for the first time with a modern twist. Setting up a modern lingerie manufacturing unit well equipped with all latest amenities was almost an unbelievable task, as far as Bhiwandi was concerned. But Sonari surely was an eye-opener in every way and helped the other brands feel confident with Bhiwandi.

“From affording land or manufacturing space in Bhiwandi to setting up an entire supply chain in the area and functioning as a singular unit, Bhiwandi does play a very important role and gives us a comfortable edge in every way. What is a very important factor is that a brand can purchase acres to set up their unit, without getting burdened with the price of setting up the manufacturing unit. Bhiwandi has been included within the ‘smart city’ plan proposed by the government and railway tracks are also being laid out to nurture better connectivity. Adding to this are the policies that the government brings to the textile and apparel sector. Of course there will be a swift progress for Bhiwandi in a short span of time,” comments Dipesh Kubadia, Director, Sonari.

With a labour strength that accommodates workers from in and around areas of Bhiwandi, Thane etc Sonari has added to the evolution of lingerie manufacturing in India by training the local worker strength. But sadly Dipesh ji adds that labour loyalty is still an issue in Bhiwandi. ” While electricity was a big challenge when we initiated a set up in the area, but I can confidently say that we have cut away from this problem quite significantly. However, the challenge at the moment is to make the labour stick to your unit. First of all getting skilled strength dedicated exclusively to lingerie making is not possible and then when we convert apparel specific workers to deliver the best for us, they easily flee away to other units offering them a little more wage,” explained Dipesh Kubadia, Director, Sonari.

“Training involves immense amount of money and patience. And when you dedicate months to setting up an unit and dedicating labours to perform some specialized work, you want to post that feel a little secured and want to confidently carry on the manufacturing. But then suddenly the worker exits one day. The quality of work and line of production surely gets affected owing to this movement of the workers,” Mr. Dipesh further adds.

Bhiwandi surely is the rising sun and is opening up newer spaces for lingerie and apparel manufacturers alike. The comfort and the positivity that this place as a manufacturing hub is offering is truly magnificent and many are vouching by the prospects that Bhiwandi is set to offer, “More than the deficiencies of the present we are concerned about the future projection and the benefits Bhiwandi is going to offer in the time to come,” comments Babubhai, Owner Director, Scan Lingerie. Scan is surely on the expansion mode and is ready to cross many a hurdles in the time to come by operating from Bhiwandi. The brand is ready to shift to their new manufacturing unit at Bhwandi by the Diwali this year and the is going to operate with a 18 thousand sq ft area as of now. But they are aiming high and in no time want to expand further. “Bhiwandi gives you many advantages. But the one that forced us to look this way, is surely the concept of uniting every bit connected to manufacturing and production under one roof. This is a tremendous advantage and will help us save on time and manpower to a great extent in the time to come. Maharashtra, specially the lingerie industry needed a manufacturing hub inclusive of benefits nearby and Bhiwandi is the bets solution to this need. Intially just after set up we might need to accommodate the labours, provide them rented places to stay or give them bus services to and fro the manufacturing unit. But once the metro lines start to work, we are hopeful that the transportation problems will reduce remarkably too,” Attaining skilled labours at a decent cost is also a plus point that Babubhai is counting on and is sure to benefit from once his set up is in full swing.

Mumbai and its nearby areas have benefitted immensely with Bhiwandi developing as a potential manufacturing years over the last few years and this in turn has freed the city from the pressures incurred through manufacturing. “De-congestion of Mumbai was possible only with Bhiwandi gaining its prosperous status over the years. We have affordable spaces in Bhiwandi and the connectivity and facilities of pick and drop provided by government, helps in easing out the traveling cost and time incurred by workers otherwise,” informs Geeta Singh, Owner Director, Avon Enterprise.

Avon has been operating out of Bhiwandi since 2008 and since then they have grown considerably owing to the facilities and the affordability of space and labour in the area. Avon has an operational 16 thousand sq ft area in Bhiwandi and their far sighted views have since the beginning helped them set up in such a way that whenever required, they have immense scope of expansion and remodeling.

Mrs. Singh mentions how she has seen the area getting nurtured by government support. The textile ministry in recent times is surely paying a lot of attention to this area, specially undertaking some textile park initiatives on the Kalyan link road off Bhiwandi and the ‘Make in India’ textile initiative. All this Mrs. Singh believes will help in the longer run to free Mumbai from the conditions of manufacturing and this shift will certainly ease out a lot of pressure on the city. Bhiwandi is surely the ray of promise that in no time is drawing attention from every sector of the apparel industry and will pull in more brands to set up for good at Bhiwandi!